Mobile unit for the production and shipment of oil

Purpose

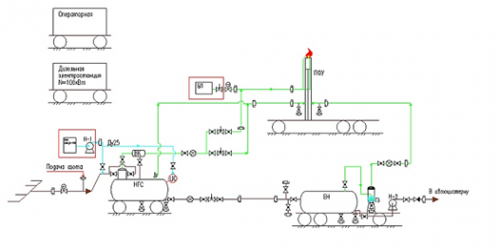

The mobile oil preparation and offloading unit is designed for automated measurement of production wells at various pressures, liquid separation with subsequent filling into tank trucks and associated gas utilization (burning) in a flare. The collection of well production after measurements is carried out both in the oil gathering system of the fields, and in its own autonomous oil and water collection system with subsequent removal in tank trucks. Associated gas utilization is envisaged in the collection system or in the flare. It is possible to use gas as a fuel for oil heating furnaces and gas power plants.

The mobile oil preparation and offloading unit is designed for automated measurement of production wells at various pressures, liquid separation with subsequent filling into tank trucks and associated gas utilization (burning) in a flare. The collection of well production after measurements is carried out both in the oil gathering system of the fields, and in its own autonomous oil and water collection system with subsequent removal in tank trucks. Associated gas utilization is envisaged in the collection system or in the flare. It is possible to use gas as a fuel for oil heating furnaces and gas power plants.

The unit can be used as a mini booster pumping station or a pre-discharge unit for exploratory wells and for trial production of deposits. In this case, the mobile installation for the preparation and shipment of oil is equipped with a unit for heating products, discharging and utilizing water.

General form

Characteristics

CharacteristicsSpecifications | |

Working environment | products of oil and gas, gas condensate wells (oil, gas, condensate, produced water) |

Performance | |

- by liquid, m3/day | from 1 to 500 (and more at the request of the customer) |

- by gas, nm3/day | from 10,000 to 2,000,000 |

- liquid mass flow measurement error | Measuring accuracy ± 2.5 mass. |

- measurement error of gas volume flow | Measurement accuracy ± 5% |

Inlet pressure (calculated), MPa | 1,6; 2,5; 4,0; 6,3; 10,0; 16,0 |

Ambient temperature, 0C | -60 to +50 |

Service life (calculated), not less than, years | 10 |

Technical details

The composition of the basic equipment

The mobile oil treatment and offloading unit includes the following process equipment (see Fig. 1) installed on separate trailer chassis or mounting frames:

1) Test separator S-1;

2) S-2 storage tank;

3) Inlet manifold block;

4) Flare Unit FU-1;

5) Unit for pumping liquid H-1;

6) a set of connecting pipelines and supports.

Mobile installation for the preparation and shipment of oil is additionally equipped with:

- oil loading unit;

- power unit (diesel gas power plant);

- reagent dosing unit;

- gas balloon installation (propane-butane, inert gas);

- well products heating unit;

- drainage tank with a pumping unit;

- mobile block-boxing operator;

- bulk water installation;

- electrical heating, thermal insulation of pipelines, devices and valves;

- Instrumentation and control equipment: sensors, actuators and a programmable logic controller, control cabinets, which are located directly in the process units.

To measure the well flow rate, an automated workstation (workstation) of the operator is used, serving the mobile unit for the preparation and shipment of oil, complete with a portable computer in industrial design and an uninterruptible power supply unit for the process control system.

The top level of the control system is responsible for ensuring full information compatibility of the technological control object and the automation system. As part of this level, the realized automated workplace of the operator. The automated workplace of the operator performs visualization of the technical process, registration of parameters according to specified conditions, generation of reports in graphic and text form, etc. workstation allows the operator to control the process.

The unit is a block and is delivered with 100% factory readiness.

Figure 1. An example is a schematic flow diagram of a mobile installation for the preparation and shipment of oil.

Figure 1. An example is a schematic flow diagram of a mobile installation for the preparation and shipment of oil.Our Contacts

7072 Business Center, Al Shmookh Building UAQ Free Trade Zone, Umm Al Quwain, UAE