The oil quality measurement and control system

The oil quality measurement and control system (QMCS) is designed for automatic operational measurement of the mass (volume) of oil; determination of its qualitative characteristics (density, moisture content, pressure, temperature); oil sampling; transfer of information to the operator's workstation.

QMCS is a part of oil treatment units (OTU), pumping stations or other surface installations of oil and gas producing enterprises

QMCS is a part of oil treatment units (OTU), pumping stations or other surface installations of oil and gas producing enterprises

Part of the equipment

The QMCS includes the following equipment:

- node of input filters;

- unit for measuring the amount of oil with flow meters (volume or mass);

- at least two measuring lines (one is a backup and verification line, the second is a working line, or three separate lines;

- block of quality control and sampling;

- drainage system from pipelines;

- block box or base frame;

- connection points for pipe piston calibration units (TP9) and devices for determining the residual gas content (RGC)

- control and measuring devices.

Block-boxes are equipped with heating, ventilation, gas control and fire alarm sensors.

Upon separate request, the QMCS is completed with a specialized device for processing data from the primary transducers of flow, humidity, temperature, and pressure installed in the QMCS.

Below is the nomenclature of the QMCS.

Upon separate request, the QMCS is completed with a specialized device for processing data from the primary transducers of flow, humidity, temperature, and pressure installed in the QMCS.

Below is the nomenclature of the QMCS.

Designation

QMCS is available in two versions: blocks of oil metering units of open design - version 1 and placed in block boxes - version 2.

Order entry example:

Oil quality measurement and control system QMCS-500-HL1, where:

500 – throughput, t/h;

HL1 - climatic version.

| Technical details | ||

| Working environment | oil after separation at the booster pumping station, oil treatment unit, preliminary water discharge unit | |

| Working mode | uninterrupted | |

| Design pressure, MPa | 4,0; 6,3 | |

| Throughput, t/h (m3/h) from 10 to 1260 | ||

| Fluid temperature, °C from +5 to +90 | ||

| Viscosity of the fluid, cSt, no more than 100 | ||

| Fulid density, kg/m3 780-950 | ||

Limits of permissible relative measurement error:

| ± 2,5 % | |

| up to 70% | ± 6 % |

| from 70% to 95% | ± 15% | |

| life cycle, not less, years | 20 | |

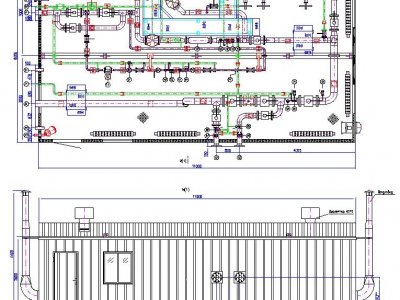

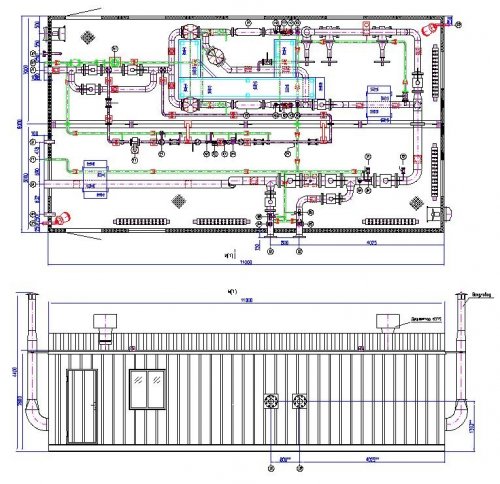

Oil quality measurement and control system QMCS-3000-2-HL1 with a capacity of 150 t/h

Explication fittings

| Name | Purpose | PN, MPa | Quantity |

| A1 | Oil input | 6,3 | 1 |

| B1 | Oil output | 6,3 | 1 |

| V1 | Unaccounted oil drainage | 6,3 | 1 |

| G1 | Accounting oil drainage | 6,3 | 1 |

| D1 | Drainage from the block floor | 1,6 | 1 |

| Z1,2 | Foam mortar for extinguishing | 6,3 | 2 |

| F1 | Entering an EA action | - | 1 |

| I1 | Cable entry for instrumentation and control | - | 1 |

| C1,2 | To the mobile verification unit "PUMA" | 6,3 | 2 |

The range of manufactured QMCS

| Options | Dimensions | ||||

| QMCS - 500 | QMCS - 1000 | QMCS - 3000 | QMCS - 5000 | QMCS -10000 | |

| Throughput, t/h | 8 – 40 | 24 – 120 | 36 – 180 | 60 – 300 | 120 – 800 |

| Nominal diameter of the measuring line, mm | 40 | 65 | 80 | 100 | 150 |

| Design pressure, MPa | 4.0-10.0 | ||||

| Fluid temperature, oC | +5+50 | ||||

Viscosity of the fluid, cSt no more | 100 | ||||

Density, kg/m3 | 780-950 | ||||

| Water cut, % no more | 90 | ||||

| Working fluids | oil, water | ||||

Our Contacts

7072 Business Center, Al Shmookh Building UAQ Free Trade Zone, Umm Al Quwain, UAE