Oil Pumping Station

Oil Pumping Station is designed to transfer oil through oil gathering and treatment systems, as well as to feed treated oil into inter-field pipelines.

Specifications

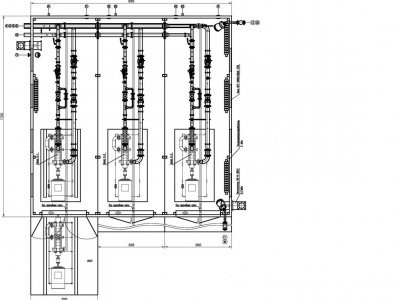

The Oil Pumping Station comes complete with centrifugal segmental-type pumps, multi-stage pumps or other types as required by the Customer, as well as with filters, process piping, isolation valves and instruments.

Oil Pumping Station can be housed in a shelter or on an open skid. It comes in various design versions and configurations made to suit the requirements of each individual customer.

Shelters are equipped with hoisting mechanisms, electric-panel or hot-water heating systems, lighting, ventilation, gas detectors and fire alarms.

At customer's option the station can be further complemented with monitoring equipment designed to monitor control and alarm systems

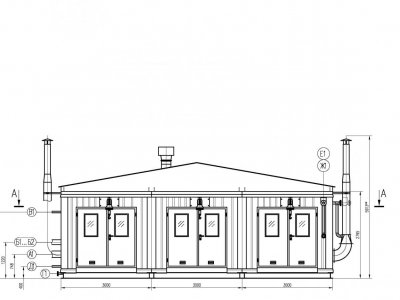

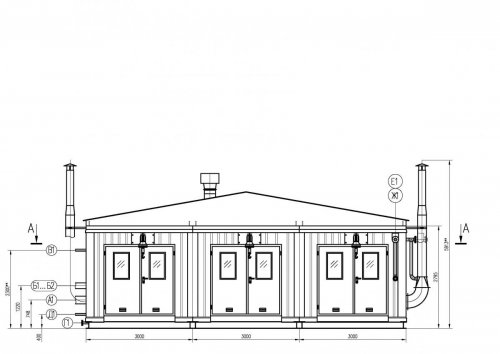

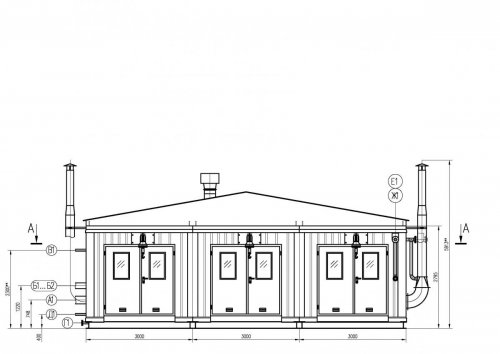

Depending on the size and the number of pumps used, the Pumping Stations are built as modular units measuring 3х9х2.95m, 3х6х2.95m.

If two, three or more pumps are to be housed in modules, modules are combined into a single process building.

Item designation

Ordering information:

Oil Pumping Station НН-300-ХЛ1 as per ТУ3667-008-56562997-2003, where:

300 refers to the capacity, m3/day;

ХЛ1 refers to the climatic rating (from –600С to +400С).

Technical Data

Technical Parameters and Specifications of Pumping Stations with Two Pump Units

As more pumps are put into combined operation, the capacity of the Pumping Station increases two or three-fold and more.

Nozzle Listing

Specifications

The Oil Pumping Station comes complete with centrifugal segmental-type pumps, multi-stage pumps or other types as required by the Customer, as well as with filters, process piping, isolation valves and instruments.

Oil Pumping Station can be housed in a shelter or on an open skid. It comes in various design versions and configurations made to suit the requirements of each individual customer.

Shelters are equipped with hoisting mechanisms, electric-panel or hot-water heating systems, lighting, ventilation, gas detectors and fire alarms.

At customer's option the station can be further complemented with monitoring equipment designed to monitor control and alarm systems

Depending on the size and the number of pumps used, the Pumping Stations are built as modular units measuring 3х9х2.95m, 3х6х2.95m.

If two, three or more pumps are to be housed in modules, modules are combined into a single process building.

Item designation

Ordering information:

Oil Pumping Station НН-300-ХЛ1 as per ТУ3667-008-56562997-2003, where:

300 refers to the capacity, m3/day;

ХЛ1 refers to the climatic rating (from –600С to +400С).

Technical Data

| Process fluid | oil |

| Single pump oil capacity, m3/h | from 13to 300 |

| Delivery head in meters of water column | from 70 to540 |

| Air temperature inside module, оС, above | + 5 |

| Building explosion and fire hazard class under Fire Safety Code - НПБ 105-03 | А |

| Fire resistance rating as per SNiP 21-01-97 | III |

| Ambient temperature, 0С | from -60 to +50 |

Technical Parameters and Specifications of Pumping Stations with Two Pump Units

| Parameters | Standard sizes | |||||

| НН-300 | НН-900 | НН-1400 | НН-2500 | НН-4300 | НН-7200 | |

| Capacity, m3/h, max. - with one pump in operation | 13 | 38 | 60 | 105 | 180 | 300 |

| Suction pressure, MPa | 0,10 – 0,2 | 0,10 – 0,2 | 0,05 – 0,6 | 0,05 – 0,6 | 0,05 – 0,6 | 0,05 - 0,6 |

| Discharge pressure, MPa | 0,7 ÷ 3,5 | 0,44 ÷ 2,2 | 0,66 ÷ 3,3 | 0,98 ÷ 4,4 | 0,85 ÷ 4,25 | 1,2 ÷ 5,4 |

| Number of pumps | 2 (1 operating + 1 standby) | |||||

| Process fluid | oil | |||||

| Process fluid temperature, оС | +1 up to +45 (+60) | |||||

| Area classification as per ПУЭ (Electrical Installations Code) | В – 1а | |||||

| Module dimensions, m: L max, W max. | 6 3 | 6 3 | 6 6 | 9 6 | 9 6 | 9 6 |

As more pumps are put into combined operation, the capacity of the Pumping Station increases two or three-fold and more.

Oil Pumping Station with Sigma pump 80-CES-200-12/14-OU-FE

Nozzle Listing

| Designation | Purpose | Qnt. |

| А1,2 | Oil inlet | 2 |

| Б1,2 | Oil outlet | 2 |

| Д | Drain | 1 |

| Р1,2 | Floor drainage | 2 |

| Х1,2 | Powr cable entry | 2 |

| Л | Instruments cable outlet | 1 |

| Э | Electrial equipment cable entry | 1 |

| П1,2 | For foam lines | 2 |

Our Contacts

7072 Business Center, Al Shmookh Building UAQ Free Trade Zone, Umm Al Quwain, UAE