Faucets

Mixers (SM) are evaluated by the value of the demulsifier with the water-and-gas mixture, providing conditions for breaking the water-oil emulsion in the underwater oil pipeline before the preliminary water discharge unit (WDU) and the oil treatment unit (OTU). The use of mixtures of lubricants in the composition of OTUs WTUs can significantly reduce the time of dynamic settling in oil treatment units.

Mixers are also used to store oil with fresh water at oil desalination sites.

Mixers are also used to store oil with fresh water at oil desalination sites.

Characteristics

Part of the equipment

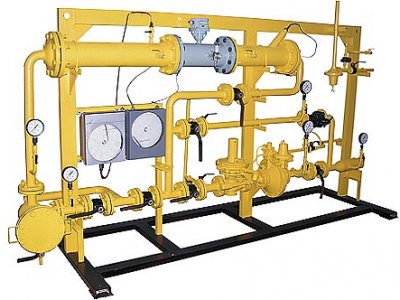

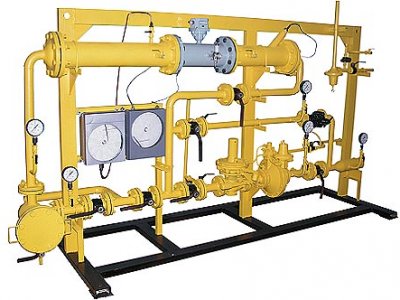

The mixer (SM) is supplied with or without a base frame, complete with piping, shut-off valves, instrumentation, service platform.

For intensive mixing of an oil emulsion with a demulsifier or oil with fresh water, internal devices of a jet or plate type are used.

The design of the mixer is determined depending on the required performance, physical and chemical properties of oil, formation water, content and nature of solid inclusions (mechanical impurities).

Designation

An example of a record when ordering products:

1) Mixer SMS-1.6-700-5-HL1, where:

SMS - jet type mixer;

1.6 – design pressure, MPa;

700 - conditional diameter, mm;

5 – length, m;

HL1 - climatic version.

2) Mixer SMP-1.6-500-2-U1, where:

SMP - plate type mixer;

1.6 – design pressure, MPa;

500 – conditional diameter, mm;

2 – length, m;

U1 - climatic version.

Technical details

| Specifications | |

| Working fluid | gas-water-oil mixture |

| Liquid load, m3/day | up to 25000 |

| Water content in oil, % wt. not limited | |

| Free gas content, % vol., no more than 50 | |

| Design pressure, MPa | 1,0; 1,6; 2,5; 4,0 |

| Operating environment temperature, 0С | от +5 - +70 |

| Ambient temperature, 0С | от -60 до +50 |

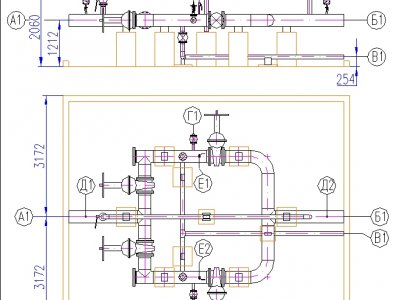

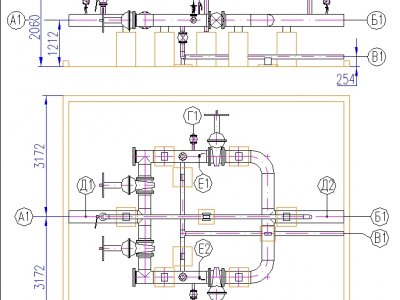

SMS-300-3-HL1 - jet type with a capacity of 5000 m3/day

| Name | Purpose | Quantity |

| A1 | Oil emulsion inlet | 1 |

| B1 | Output of oil emulsion | 1 |

| V1 | Drainage | 1 |

| G1,2 | For steaming | 2 |

| D1,2 | For pressure gauge | 2 |

| E1,2 | Air vent | 2 |

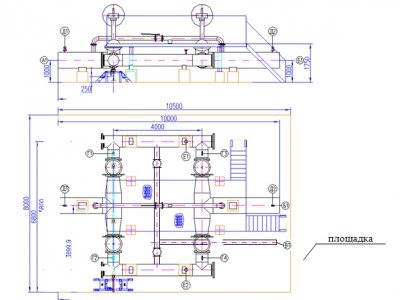

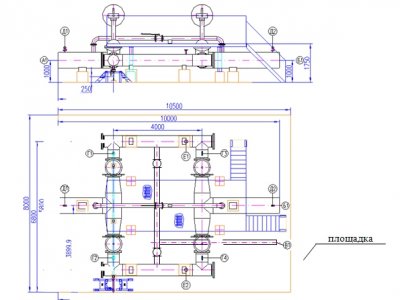

SMP-500-3-HL1 - lamellar type with a capacity of 25000 m3 / day

| Name | Purpose | Quantity. |

| A1 | Oil emulsion inlet | 1 |

| B1 | Output of oil emulsion | 1 |

| V1 | Drainage | 1 |

| G1,2,3,4 | For pressure gauge | 4 |

| D1,2 | For pressure sensor | 2 |

| E1,2 | For steaming | 2 |

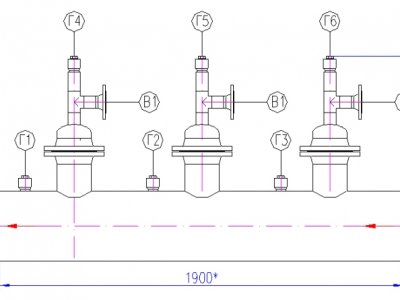

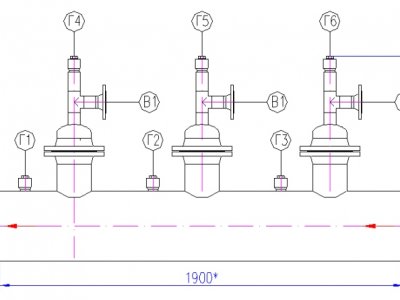

SM-300-3-HL1 with a capacity of 15,000 m3/day

| Explication fittings | |||

| Name | Purpose | DN, mm | Quantity |

| A1 | Oil emulsion inlet | 300 | 1 |

| B1 | Output of oil emulsion | 300 | 1 |

| V1,2,3 | Fresh water inlet | 50 | 3 |

| G1-6 | For pressure gauge | G1/2 | 4 |

Parameters of produced liquid mixers

| Mixer designation | Throughput performance by liquid, m3/day | Mixer body diameter DN, mm | Case length, mm |

| SMS-700 | 20000-25000 | 700 | 3000-5000 |

| SMP-500 | 500 | ||

| SMS-600 | 15000-20000 | 600 | 3000-5000 |

| SMP-500 | 500 | ||

| SMS-500 | 7500-15000 | 500 | 3000-5000 |

| SMP-400 | 400 | ||

| SMS-400 | 5000-7500 | 400 | 2000-4000 |

| SMP-300 | 300 | ||

| SMS-350 | 3000-5000 | 350 | 2000-3000 |

| SMP-300 | 300 | ||

| SMS-300 | 1500-2500 | 300 | 2000-3000 |

| SMP-200 | 200 | ||

| SMS-250 | 500-1000 | 250 | 2000-3000 |

| SMP-200 | 200 |

Our Contacts

7072 Business Center, Al Shmookh Building UAQ Free Trade Zone, Umm Al Quwain, UAE