Modular automated oil treatment units

Modular automated oil treatment units are designed for gathering and treatment of products of oil wells by providing deep dehydration, desalination, and oil vapor pressure reduction to achieve the saleable quality of oil and discharged stratal water for further transportation.

Characteristics

Technical specification

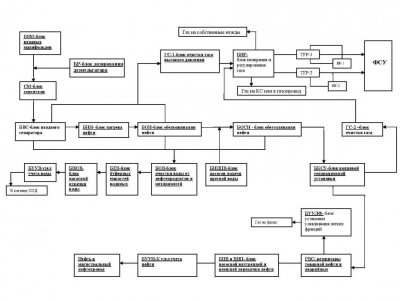

Basic sets of modular automated oil treatment units:

- inlet manifold system;

- demulsifier dosing skid;

- block of stimulation of intermixing of liquid-gas mixture with a demulsifier (mixing vessels);

- block of inlet separator with water discharge;

- oil heating unit;

- oil dehydration vessel;

- oil desalting unit;

- block of fresh water supply pumps;

- block of terminal separation unit;

- stratal water treatment unit;

- block of buffer water tanks;

- block of pumps for internal and external oil pumping;

- water pumping unit;

- gas purification unit of high and low pressure GS-1 and GS-2;

- gas measuring and controlling unit;

- block of oil metering station commercial;

- block of pipe gas expanders acting as flare separators;

- combined flare units of high and low pressure;

- block of emergency tanks;

- blocks of drainage tanks;

- blocks of drainage tanks, oil spills, gas condensate gathering and emergency emptying of oil heating units;

- hydrocarbon vapour recovery unit;

- operator control block;

- block of a chemical laboratory;

- block of machine shop;

- transformer substation block and switchgear;

- block of control switchboard;

- block of pumping fire fighting system;

- block of fire water storage reservoir;

- block of auxiliary equipment;

- a set of hardware and software applications and automated process control systems.

The oil treatment units can be manufactured both in drum-based and tubular designs.

The configuration of well-products treatment units will be determined for each individual field based on research work carried out by the company.

The development, manufacture and supply of the modular complex of the oil treatment unit of maximum factory readiness is performed in 6-8 months.

Advantages of the technology of Polyexpim FZE

Polyexpim FZE developed complete production lines for oil treatment, consisting of two and more parallel chains. Complete production lines can be performed both in tank and pipe variants.

In order to stimulate the processes of gas separation, oil dehydration and water treatment the vessel design contains built-in internal devices such as coalescers, multiple deck settlers and other hydrodynamic devices and tools.

The design concept of constructing technological schemes, equipment configuration the level of fabrication coupled with the specific “know-how” have been formulated as our “express technology”.

The “express technology” enables us to improve our project design and equipment performance two-or threefold versus the conventional (industry standard) technologies in terms of reliability, efficiency, metal consumption and capital costs.

Packaging arrangement of the Oil Treatment Unit as Complete production lines enables to supply equipment as fully preassembled units to be commissioned sequentially in each phase, to ramp up oil treatment unit capacity incrementally as the field development progresses, and to spend construction funds more rationally.

The complex scheme includes an extensive range of equipment rated according to the characteristics of the product to be treated.

If the characteristics of the product are less demanding, we offer a simpler design. For instance, light and medium crude oil can be dehydrated to marketable standards already in the first separation and dehydration stage with minimum or no heat input to assist the process and with minimal consumption of demulsifiers (up to 15-30g per ton of oil).

Characteristics

| Technical Data | |

| Capacity - for liquids, mln.t/year: | 0,3;0,5;1,0;3,0;6,0;9,0 |

| - for oil, t/day (rated) | 1000;1600;3000;5000;10 000;15 000;25 000 |

| - for gas, mln.nm3/day (rated) | 0,1;0,16;0,3;0,5;1,0;1,5;3,0 |

| Water-in-oil content, % mass. | |

| - at inlet | Up to 30 |

| - at outlet | Up to 0,5 |

Quality requirements for commercial oil | As per GOST 51858-2002 |

Treated water content, mg/l | |

- oil products | Up to 40 (or lower as required by Customer) |

| - solids | Up to 40 (or lower as required by Customer) |

| Ambient temperature, ?С | From -60 up to +50 |

| Service durability, no less than, years | 15 |

Technical specification

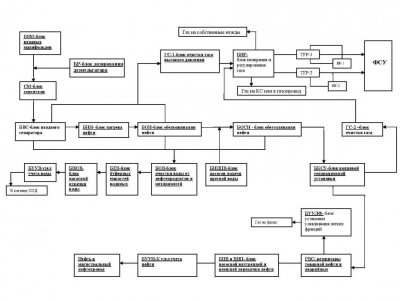

Basic sets of modular automated oil treatment units:

- inlet manifold system;

- demulsifier dosing skid;

- block of stimulation of intermixing of liquid-gas mixture with a demulsifier (mixing vessels);

- block of inlet separator with water discharge;

- oil heating unit;

- oil dehydration vessel;

- oil desalting unit;

- block of fresh water supply pumps;

- block of terminal separation unit;

- stratal water treatment unit;

- block of buffer water tanks;

- block of pumps for internal and external oil pumping;

- water pumping unit;

- gas purification unit of high and low pressure GS-1 and GS-2;

- gas measuring and controlling unit;

- block of oil metering station commercial;

- block of pipe gas expanders acting as flare separators;

- combined flare units of high and low pressure;

- block of emergency tanks;

- blocks of drainage tanks;

- blocks of drainage tanks, oil spills, gas condensate gathering and emergency emptying of oil heating units;

- hydrocarbon vapour recovery unit;

- operator control block;

- block of a chemical laboratory;

- block of machine shop;

- transformer substation block and switchgear;

- block of control switchboard;

- block of pumping fire fighting system;

- block of fire water storage reservoir;

- block of auxiliary equipment;

- a set of hardware and software applications and automated process control systems.

The oil treatment units can be manufactured both in drum-based and tubular designs.

The configuration of well-products treatment units will be determined for each individual field based on research work carried out by the company.

The development, manufacture and supply of the modular complex of the oil treatment unit of maximum factory readiness is performed in 6-8 months.

Advantages of the technology of Polyexpim FZE

Polyexpim FZE developed complete production lines for oil treatment, consisting of two and more parallel chains. Complete production lines can be performed both in tank and pipe variants.

In order to stimulate the processes of gas separation, oil dehydration and water treatment the vessel design contains built-in internal devices such as coalescers, multiple deck settlers and other hydrodynamic devices and tools.

The design concept of constructing technological schemes, equipment configuration the level of fabrication coupled with the specific “know-how” have been formulated as our “express technology”.

The “express technology” enables us to improve our project design and equipment performance two-or threefold versus the conventional (industry standard) technologies in terms of reliability, efficiency, metal consumption and capital costs.

Packaging arrangement of the Oil Treatment Unit as Complete production lines enables to supply equipment as fully preassembled units to be commissioned sequentially in each phase, to ramp up oil treatment unit capacity incrementally as the field development progresses, and to spend construction funds more rationally.

The complex scheme includes an extensive range of equipment rated according to the characteristics of the product to be treated.

If the characteristics of the product are less demanding, we offer a simpler design. For instance, light and medium crude oil can be dehydrated to marketable standards already in the first separation and dehydration stage with minimum or no heat input to assist the process and with minimal consumption of demulsifiers (up to 15-30g per ton of oil).

Our Contacts

7072 Business Center, Al Shmookh Building UAQ Free Trade Zone, Umm Al Quwain, UAE